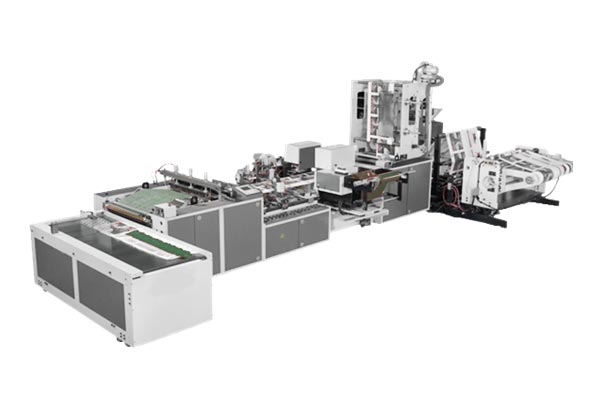

The Automatic machine will convert either a Tubular roll or a Lay flat film into a Side Seal bag and Attach the Loop handle or a Reinforced Patch handle Automatically inline on the machine. The machine is equipped with a Dual Servo System for higher productivity and to maintain tension on the film. The machine is capable of running upto a maximum speed of 100 Strokes/min.

Automatic Soft Loop & Patch Handle Bag Machine Features :

- Reclosable Tape Applicator

- Double Lip Sealer for Top Inside Fold

- Auto Stacker

- Pneumatic Euro (Hanger) Punch

- Pneumatic Hole Punch Bank

- Sheet Folding Device

- Pneumatic Chicken Bag Attachment (Round Bottom)

- Pneumatic Wicketing Attachment

- Ultrasonic Seal Attachment with Pearl Insert

Automatic Soft Loop & Patch Handle Bag Machine Attachments :

The following optional attachments / tools are available to add features to the machine and make variety of bag structures:

- Reclosable Tape Applicator

- Double Lip Sealer for Top Inside Fold

- Pneumatic Euro (Hanger) Punch

- Pneumatic Hole Punch Bank

- Sheet Folding Device

- Auto Stacker

- Pneumatic Chicken Bag Attachment (Round Bottom)

- Ultrasonic Seal Attachment with Pearl Insert

- Pneumatic Wicketing Attachment

Types Of Bags That Can Be Made

Automatic Soft Loop & Patch Handle Bag Machine Technical Specification :

| Handle | Bag Width | Bag Length | Tap Fold | Bottom Gust | Thickness | Max.Speed | Connected | Weight | Comp.Air | Dimensions |

| Type | mm | mm | mm | Max. mm | Microns | Bags/min | Load KW | Kg. | cfm | WxLxH cms |

| Soft Loop | 280-500 | 250-600 | 70-75 | 75 | 50-90 | 80 | 14 | 3300 | 25 – 30 | 255 X 828 X 202 |

| Patch | 250-500 | 250-600 | – | 75 | 50-90 | 75 | ||||

| Die Cut | 250-500 | 250-600 | – | 75 | 50-90- | 120 | ||||